Just to keep everything straight, I’ve decided to dedicate this page to the build of the bus, adding time dates and estimates so everyone can follow along. Relevant blog articles will be linked in the timeline.

Pre-Build Milestones

- Contacted The Rolling Donkey about getting a bus conversion done 7/20/21

- Finalized the design 10/13/21; Down payment made

- The Bus is purchased by The Rolling Donkey 10/19/2021!!!!

The next steps are going to be gutting, raising the roof, and adding all the systems. As soon as these are done, I’ll update the page.

Gutting! 10/30/21

Just heard from The Rolling Donkey today that they are about 95% done gutting the bus. All unneeded wires are gone. The underbody, indoor AC units, and heaters are out. The old sub-flooring, ceiling, and wall paneling have also been removed, including most of the old seats.

Raise the Roof! 11/5/21

Today, we heard that The Rolling Donkey is about 1/2 done with the roof raise!

Since we’re planning to live in this for quite some time, we wanted to have the roof raised an additional 12 inches so we wouldn’t have to stoop when we stood up. Even though we’re planning to spend most of our days outside, it is still important to consider comforts like this. Along with the roof raise, we’ve had to make some changes to the floor plan due to wheel well placement. We almost had an opportunity to have the emergency door open directly into the bathroom to allow access from the outside (think muddy children), but this ended up being more of a hassle than we wanted to deal with and would have shifted our floor plan further. A fun idea, though.

More Roof Progress 11/10/2021

We’ve had to adjust some of the final window placements as they would have a negative impact on the structural integrity of the bus, however, The Rolling Donkey is making amazing progress! Once all the struts are welded up, they will add sheet metal to the outside and cut holes for the new windows.

More Roof Progress 11/24/2021

The roof raise is still in progress, 50% of the bus has been sheeted with 18-gauge sheet metal, and all mild steel has been primed.

The gray tank mounts are being fabricated and the roof raise should be completed in the next 10 days. The Rolling Donkey was also able to get a better deal on some parts and has increased the propane capacity from 12 to 20 gallons.

More Roof Progress 12/06/2021

The Rolling Donkey is just about completed with the “transition” section of the roof raise, going from the max height in the living area down to the stock size of the driving area. They are going to install a headliner on the ceiling of the driving area, too, to make sure the ceiling is a little softer. Furring strips are being installed along the ceiling to give space for insulation and to prevent thermal bridging, and framing of the walls has begun. The floor has been primed, and the subfloor joists are being installed. Soon, The Rolling Donkey will start rough electrical and plumbing, installing gray and freshwater tanks, and everything else needed for the initial NOAH inspection.

The Roof is Done! 12/20/2021

The roof raise is essentially complete! Windows are getting installed and the gray water tanks (originally we planned on just one, but ended up needing to do two, one in the kitchen, and one off the shower) were successfully installed the other day. The propane tank should be going in today, too!

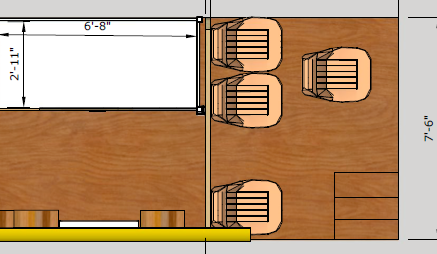

As with all projects, there have been some changes made due to the bus not quite matching the sketch. Originally, the driving area was going to look a little like this:

However, the way everything lined up, the passenger seats would sit right over the wheel wells. The Rolling Donkey was able to fabricate a bracket for the side-by-side seats behind the driver, however, it would not have worked for the single seat.

The Rolling Donkey will now put the single passenger seat beside the driver seat on a slide to facilitate the driver getting into and out of the seat. They also had to make some minor changes to the awning placement, and we’re still figuring out the dimensions for the under-bus storage bays. Once all this structural work is done, it should really start flying!

Fitting It Out 1/14/2022

Things are really starting to speed up. The Rolling Donkey sent us a final sketch of the interior, adding the wheel wells.

Progress to date:

All rough electrical and most rough plumbing has been done.

Kitchen vent, outdoor shower installed. Mounted the outside AC unit.

Outlets and light switches have been placed. And walls have been framed, the subfloor is complete and ready for flooring.

Skylights and ceiling insulation are ready to go up.

Insulation and more! 1/28/2022

The Rolling Donkey just sent us a fresh update! We’ve got the roof insulated, skylights are going in, and the under-bus storage compartments are almost done!

It’s out of the shop 2/8/2022

Also some more inside progress. The ceiling is coming along great and the freshwater tank has been installed. The master bed will cover it up.

Not much left to do! Cabinets, bed framing, solar system, and other kitting out. The Rolling Donkey is now estimating completion by March 1st: 3 weeks!

Painted and pretty 3/3/2022

The Rolling Donkey has gotten the bus back from their body shop partner and it’s looking good!

We’re in the home stretch! Just waiting on the seats to be delivered and the cabinetry to be finished. The exterior still needs cargo doors, an awning, and the solar array mounted, then there is installing the needed systems. Hoping to hear back any day that it is ready for pickup!

Getting So Close!!! 3/20/22

A fresh update from The Rolling Donkey! The kids’ seats finally arrived! Now we’re only waiting on some components for the solar system. Meanwhile, a whole lot of systems have been installed, including a backup camera, Wi-Fi, stove, refrigerator, water heater control panel, thermostats, water tank monitoring system, carbon monoxide/propane leak detectors, and base cabinets. The finishing touches are going into the liquid propane system and the walls are fully insulated! Still (hopefully) on track for an end-of-March delivery.

Supplier delays…. 3/27/21

We reached out to The Rolling Donkey about an updated delivery date, as the last soft date was the 28th. They got back to us rather quickly that they were still waiting on a component for the solar system, but their supplier said they should have the part to them by the 5th. Tentatively, our bus should be ready for pickup by April 10th. The delays are frustrating, but we can’t get too worked up over them as they are well out of anyone’s control.

Bonus pictures though!

All Parts Are on Site!!!!! 4/8/2022

Heard from The Rolling Donkey; the solar panels finally arrived!!

The Rolling Donkey says they are on track for a 4/16/2022 completion date and are doing everything they can to expedite completion.

Weather Delays…. 4/14/2022

Reached out to The Rolling Donkey about the 4/16 delivery. Regrettably, the weather in Idaho has been uncooperative and they lack the ability to mount the solar panels inside their workshop; the owner has said that he’s putting in 16-hour days to try and expedite the build, regardless.

Delivery! Sort of… 4/20/2022

We reached out to the Rolling Donkey several days ago, more than a little frustrated with the repeated delays. Looking over the contract we had with them, it was clear that they were in breach of contract. We told them to put a halt on any cosmetic work and to just focus on finishing the systems that I wasn’t confident in my ability to tackle. We also decided to send me down to their production facility to lend a hand. It was frustrating, to say the least.

I have a background in lean manufacturing and strive daily to eliminate waste and facilitate efficiency. Each day, the builders seemed to spend more time looking for tools than using them, and a lot of time figuring out what to do next. I could have easily written reams on where they could have been better, had I been hired on as a consultant. As it was, I just bit my lip and did what work I could to get the bus ready to drive back to Buckley.

Home, but far from done… 4/27/2022

We got the electrical system finished, appliances installed, plumbing sorted, and a fair amount of the trim work done while I was in Idaho helping, and it was time to drive the bus home. Now, when we contracted with The Rolling Donkey, they said they would perform mechanical checks on the bus’s motor and drive train and it would be good to go, but this clearly didn’t happen. Driving the bus home over the Cascades, there was a noticeable lack of power on hills and occasional check engine lights under load. This was on top of a persistent ABS error that The Rolling Donkey said was most likely a dirty sensor. Before doing a lot of finishing work, we wanted to get the bus checked out by a qualified mechanic. We took it to Freightliner in Olympia due to their positive reviews and familiarity with the Thomas Built Saf-T-Liner.

To be blunt, there were other problems.

- Coolant filter needed replacement

- Oil feed line for the Huey pump was leaking (badly)

- The hydraulic fan motor was leaking

- Differential fluid needed replacement

- Power mirrors didn’t work

- Tail lights weren’t working

- Air filter was plugged with sand

- Airbrake system leaked excessively

- Steering hubs were low

- One headlight worked in high beam, the other only in low beam.

- Fuel pump solenoid was not working right, causing the check engine light.

Most of these were quick repairs (the ABS light was just a missing fuse), but the hydraulic fan, essential for rear-engine pushers, was on backorder. Actually, it wasn’t made anymore and the lead time for a shop to fabricate one was 4 months out… I was able to get a refurbished unit from AAA Bus Sales in Phoenix, Arizona, though, and due to the lead time, Freightliner agreed to install the part. Even though we got them the right parts, it still took them 10 weeks to get the work done.

Back Home, Finishing the Details and Fixing Problems… 7/12/2022

We finally got the bus back home and dove into finishing up the pretty stuff, testing and repairing systems, and getting it ready to launch. While our original hope was to launch in May, as we had arranged a workamping position in Montana, the delays at the mechanic and The Rolling Donkey changed that.

Other Problems Not Pictured:

Both the bathroom sink and shower were plumbed with the wrong kind of drains, causing them to leak under the floor and counter.

The propane furnace didn’t work; it wasn’t discovered until later that a switch, behind a silicone-sealed panel, was in the off position.

Oh, and the front door to the bus would randomly open when driving.

Launch and Beyond …

We eventually did launch in August 2022, and there is something new every day. A new repair to make. A new shortcut was found. A small upgrade to make. It hasn’t been seamless, but we’re happy. Every day, I’m reminded of a quote from Neil Gaiman: “A novel is never finished, only abandoned.” I think skoolies are the same.

The Stats

Throughout this build, I hinted at many features of the bus but never put a whole list of what she’s got. Here it is!

This post may contain affiliate links, meaning if you click on it and make a purchase I’ll receive a small commission at no cost to you. As an Amazon Associate, I earn from qualifying purchases. For more information, please check our Privacy Policy and Disclaimers and Disclosures.

- 40ft Thomas Built Saf-T-Liner diesel pusher school bus, 2007, with a custom 12-inch roof raise

- 4-season insulation in ceiling, floors, and walls

- Reinforced 2-inch wall behind seats, steel supports welded to the chassis, finishing with sanded plywood

- Seating with seat belts for 2 kids and 2 adults

- 2 100-gallon freshwater tanks

- 150-gallon gray tank (actually, 2 gray tanks; one is 50 gallons and one is 100 gallons)

- 30″x30″ custom shower stall

- Water-saving shower head

- Separett Villa Toilet with urine diverted to 50-gallon gray tank

- Bathroom vanity and sink

- Outdoor shower head

- 2 Storage bays under bus

- Custom under-storage compartment with pull-out table for Weber q1200 gas grill (we’ve since sold the grill and use this compartment to store a generator)

- 20ft manual awning

- Tankless propane water heater

- Horizontal 20-gallon propane tank

- 2-in-1 oven and 3-burner stove

- 7.0 cu 3-way fridge

- Microwave

- Dual-side stainless steel kitchen sink

- Baltic Birch Butcher Block countertop

- First Alert: 2 CO and 2 fire detectors

- 2 Victron Multiplus 3000-watt inverter chargers

- AIMS battery monitor

- 300 amp/h lithium-ion battery bank

- Solar charge controller and monitor

- 2200-watt solar array and mounts 360-watt LG panels

- 12v to 24v step-up converter

- 12v-24v fuse box

- Ceiling lights (LED)

- Alternator split charger

- Dual-zone mini split AC

- Max air fan mid-bus

- Propane RV furnace 30-40btu

- Backup camera

- Mobile Must Have Full-Time RV & Boat Internet Access Bundle

- Two non-opening skylights; the kitchen’s is 24″x18″, and the bathroom’s is 48″x24″, with a 13″x13″ notch for our bathroom ceiling fan

- Exterior paint for school bus

- Complete exchange of bus windows with RV windows (in the living area, we have 5 windows that are each 24″x36″; there are 2 24″x24″ RV windows in the driving cab)

Future Upgrades?

We’ve already talked about upping the battery bank, and we’re always making little tweaks. Watch the blog for all our exciting adventures and developments!

Hi There!

I’m Kristen, I actually just picked up my bus from the Rolling Donkey and am wondering if I could ask you a question about the furnace. And how you flipped the switch?

If so, please let me know and I can provide more details. ?

Thank you!!!

Kristen

P.S. I think we have a similar if not exact bus, a 2003 Thomas HDX ?

There should be an access panel on the outside of your bus, where the exhaust from the furnace is directed. It’s held on by 4 screws, and if The Rolling Donkey did the same with your bus as ours, has been glued shut with sealant. Remove the screws and cut through the sealant and you should have access to the ‘back’ of your furnace. The on/off switch is easy to see. Once it’s on you can just reattach the panel with the 4 screws. The sealant isn’t necessary, as the panel has a gasket.

Feel free to email me and Dad@daddingontheroad.com if you need more help.